| HH-P Aerogel Paste |

|

1.Introduction

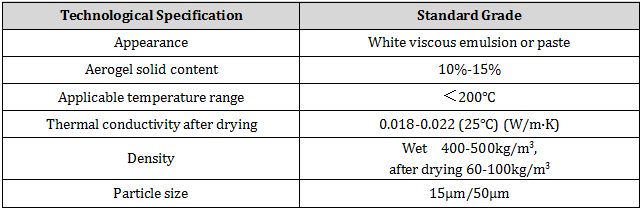

2.Product Parameters

3.Application 1, Coating additives, especially in waterborne thermal insulation coating systems, can be widely used. 2, Coating raw materials, directly used as raw materials for coatings to produce high-efficiency thermal insulation coatings. 3, Composite insulation materials for building materials, perlite materials, rock wool materials, glass fiber materials, etc. 4, Heat insulation paper industry, ultra-thin insulation materials. Application of new energy vehicles, electronic insulation materials special parts.

4.Usage Brush coating, roll coating or use a spray gun. 5.Package Packing in drum. 6.Precautions 1, Before the paste is used, there is a layered liquid at the bottom, which is normal, and it can be used after stirring evenly. 2, For the liquid at the bottom of the paste, customers can adjust the viscosity according to their needs, or add no more than 50% of water to adjust the viscosity. 3, When dust occurs during operation, customers can first use the liquid at the bottom of the paste, or add no more than 50% of water to cover the surface of the wet paste, then slowly stir to become a wet paste, and finally high-speed stirring before use. 4, After use, the paste must be sealed and protected from light in an environment below 28°C. 5, It is recommended that customers add a small amount of water and stir every other month, and the shelf life of the paste can be extended to more than 6 months. The amount of water added can be controlled according to the state of the paste. 6, The paste can be used in alkaline or acidic environment, but it is not suitable to be mixed with organic solvents in large quantities. 7, The amount of aerogel paste added to coatings or composite materials ranges from 35% to 70%. 7.Storage Mode Please keep the packing sealed and store in a dry and ventilated place. Do not mix with other volatile chemicals to prevent aerogels from absorbing these substances. The shelf life is 6 months,the storage temperature is 5-35 ℃. |

HH-P aerogel paste is a paste with high-performance SiO2 aerogel as the main raw material and a unique special process to disperse hydrophobic SiO2 aerogel particles in an aqueous medium. This product has high-efficiency thermal insulation properties. It perfectly solves the dust problem of the aerogel during use and transportation, and retains the structure of the aerogel to the greatest extent. The thermal conductivity of the dried coating of the paste at room temperature can be as low as 0.018W/m⋅k, and the density of the dry paste is as low as 60kg/m³. After drying, the water-based aerogel paste will show hydrophobic properties. Aerogel paste is an ideal additive for lightweight, high-efficiency heat insulation and waterproof materials, especially in some water-based heat insulation coatings and other composite heat insulation materials with excellent use effects.

HH-P aerogel paste is a paste with high-performance SiO2 aerogel as the main raw material and a unique special process to disperse hydrophobic SiO2 aerogel particles in an aqueous medium. This product has high-efficiency thermal insulation properties. It perfectly solves the dust problem of the aerogel during use and transportation, and retains the structure of the aerogel to the greatest extent. The thermal conductivity of the dried coating of the paste at room temperature can be as low as 0.018W/m⋅k, and the density of the dry paste is as low as 60kg/m³. After drying, the water-based aerogel paste will show hydrophobic properties. Aerogel paste is an ideal additive for lightweight, high-efficiency heat insulation and waterproof materials, especially in some water-based heat insulation coatings and other composite heat insulation materials with excellent use effects.